This is one of the more critical factors that determine an end mill’s performance. If the number of blades on an end mill is small, it would result in a small cross-sectional area and, thus, reduce stiffness, which may cause bending during cutting, but on the other hand there is a large space for discharge of chips, which makes the discharge convenient. If the number of blades is large, the chip pocket becomes small to allow a reduced capacity for chip storage but, conversely, its cross-sectional area as well as stiffness increase.

The performance of an end mill varies depending on the settings such as the number of blades, twist angle, inclination angle, relief angle and coating type, and a suitable shape is required for high-speed cutting operations.

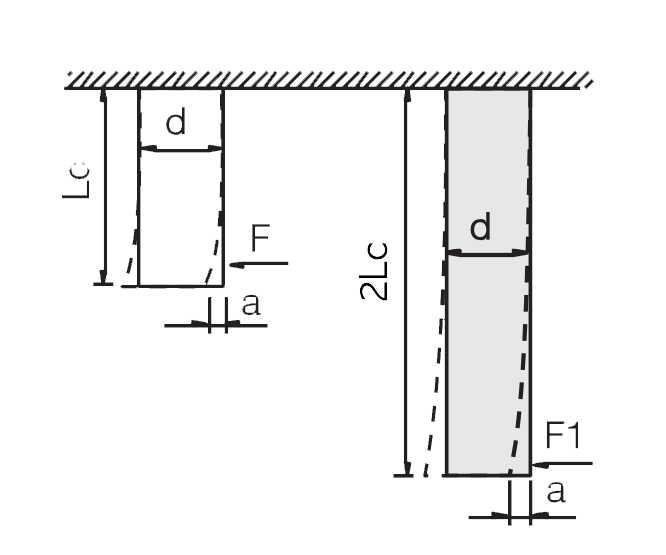

The shorter length of tools, the higher the rigidity and performance of cutting. The length of the flute become twice, the rigidity of end mills falls to 1/8. Because end mills are the tools to move horizontal, it is important for the rigidity of tools to be in inverse proportion to the length of tools. Using a longer flute that need be is not good. You can choose suitable flutes for your cutting conditions now that COGO TOOLS, we have a variety of items.

Low twist angle (below 20) : Used for applications that require precision in processed width and inclination

Medium twist angle (20 to 30) : Used for typical processing

High twist angle (above 45) : Primarily used for side cutting thanks to its outstanding machinability, and also used on light allows such as aluminum and difficult to cut processing